The Role of FPCBs in Electric Cars: A Look into the Next Five Years

Flexible Printed Circuit Boards (FPCBs) are a critical component in the development and production of electric vehicles (EVs). They play a crucial role in the functioning of various systems within EVs, such as the battery management system, the power train system, and the control and display system. In the next five years, the demand for FPCBs in the electric car market is expected to grow significantly. This article provides a comprehensive overview of the role of FPCBs in electric cars and the impact they are expected to have on the industry in the next five years.

Introduction to FPCBs

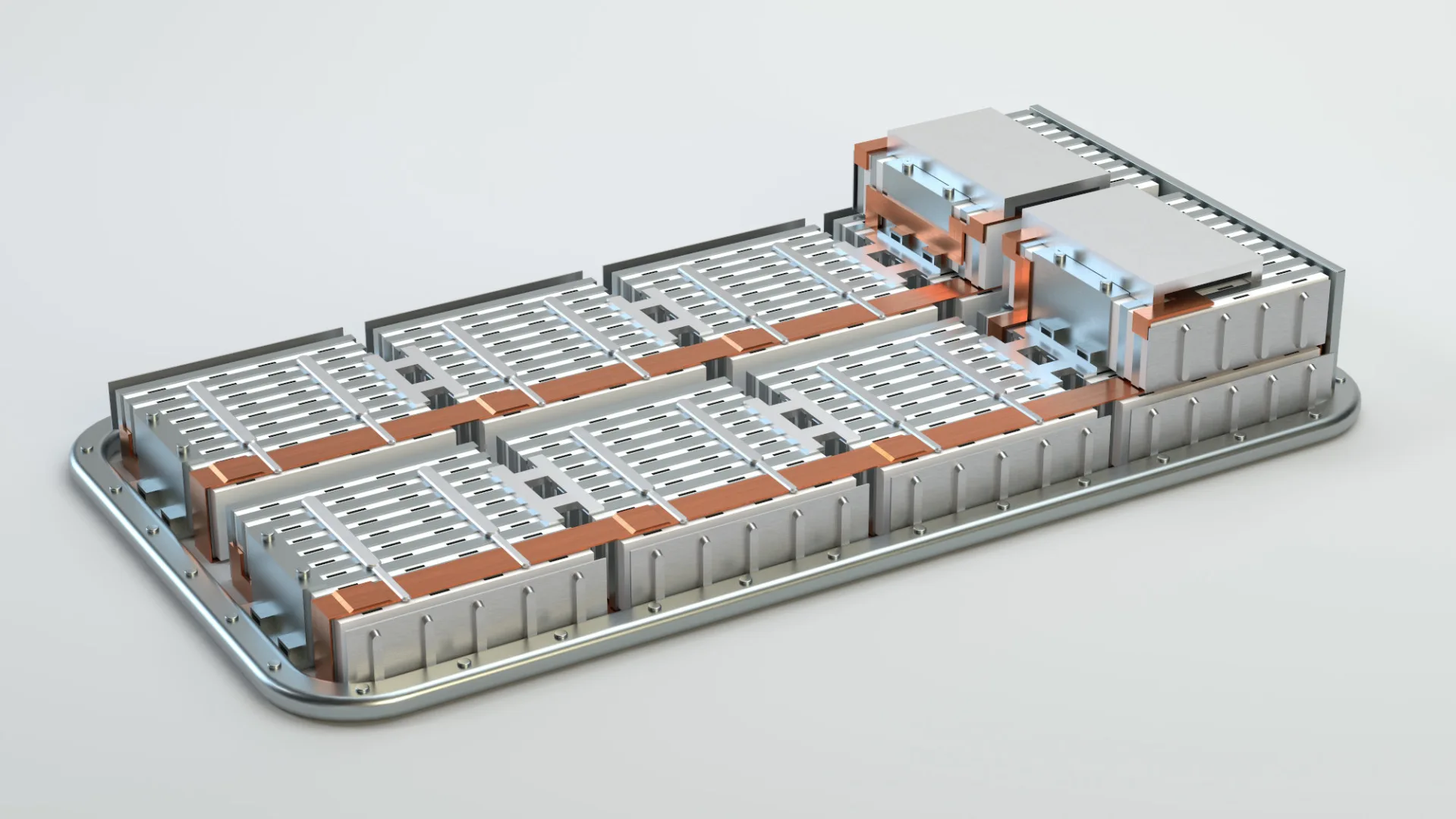

FPCBs are thin and flexible circuit boards that are used in a wide range of electronic devices. They are made of a thin layer of conductive material, such as copper, and are placed on a flexible substrate material, such as polyimide. The flexibility of FPCBs makes them ideal for use in electronic devices that require the circuit board to bend or conform to a specific shape. This is particularly important in the case of EVs, where the limited space within the vehicle means that components must be compact and flexible.

The Importance of FPCBs in Electric Cars

FPCBs are

critical components in the production of EVs for several reasons. Firstly, they

are essential for ensuring the efficient functioning of various systems within

the vehicle. For example, the battery management system requires FPCBs to

control and monitor the charging and discharging of the batteries. Similarly,

the power train system relies on FPCBs to control the distribution of power to

the vehicle's wheels.

Another important function of FPCBs in EVs is to provide a reliable and safe connection between different components. This is particularly important in high-voltage systems, such as the battery management system, where a reliable connection is essential for the safety of the vehicle and its passengers.

Finally, FPCBs are essential for the integration of various systems within the vehicle. The control and display system, for example, requires FPCBs to provide a connection between the display screen and the vehicle's onboard computer.

The Future of FPCBs in Electric Cars

In the next five years, the demand for FPCBs in the electric car market is expected to grow significantly. This is due to several factors, including the increasing demand for EVs, the need for improved performance and safety in these vehicles, and the continued development of new technologies.

One of the key trends in the electric car market is the increasing use of high-voltage systems, such as the battery management system. This trend is expected to continue in the coming years, which will drive the demand for FPCBs with higher performance capabilities.

In addition, the need for improved safety in EVs is also expected to drive the demand for FPCBs. This is because FPCBs play a critical role in ensuring the reliable and safe functioning of high-voltage systems, such as the battery management system.

Finally, the continued development of new technologies in the electric car market is expected to drive the demand for FPCBs. For example, the integration of advanced driver assistance systems (ADAS) and autonomous driving technologies is expected to increase the demand for FPCBs with higher performance capabilities.

Conclusion

In

conclusion, FPCBs are critical components in the production of electric

vehicles and are expected to play an even more important role in the next five

years. With the increasing demand for EVs, the need for improved performance

and safety, and the continued development of new technologies, the demand for

FPCBs is expected to grow significantly

Learn more about Flex Plus's commitment on EV Electric Car Industry

Flex Plus works closely with clients to ensure its supplied FPC to ensure customers' success and satisfaction.

Contact: gm02@fpc-plus.com