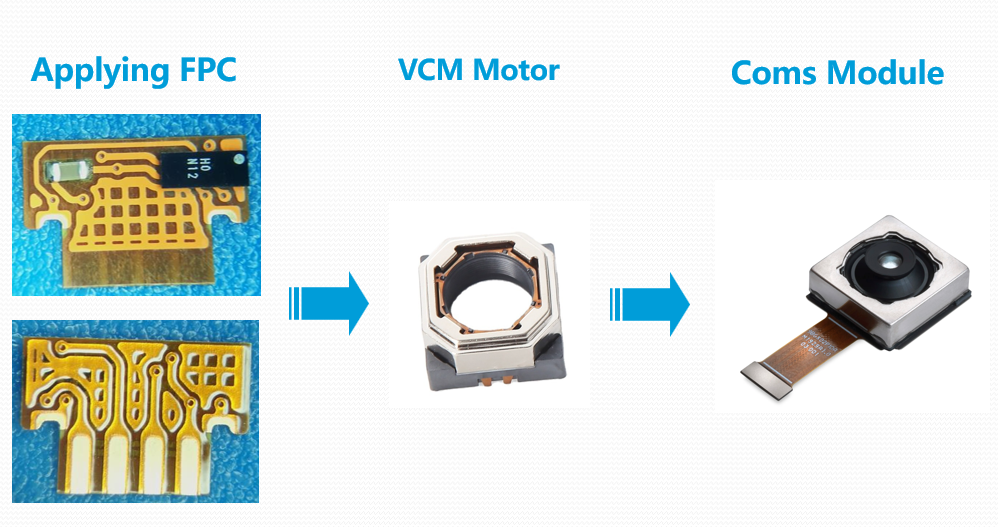

Flex Plus's Innovative FPC Solutions for VCM(Voice Coil Motor) Manufacturing

Flex Plus is a Chinese FPC factory company that specializes in producing high-quality FPCB for VCM (Voice Coil Motors). The article explains the reasons behind the company's expertise in this area. The main strengths of Flex Plus's manufacturing process for FPCB include control of solder joint voids, inhibition of solder balls, balance of the alloy layer, control of board surface flatness, application of underfill, and unique packaging design. The article further elaborates on each of these strengths, providing a demonstration, causes, countermeasures, and instructions to ensure that the FPCB produced by Flex Plus is of the highest quality. Overall, Flex Plus's expertise and attention to detail make it an excellent choice for customers seeking reliable and high-quality FPCB for VCM applications.

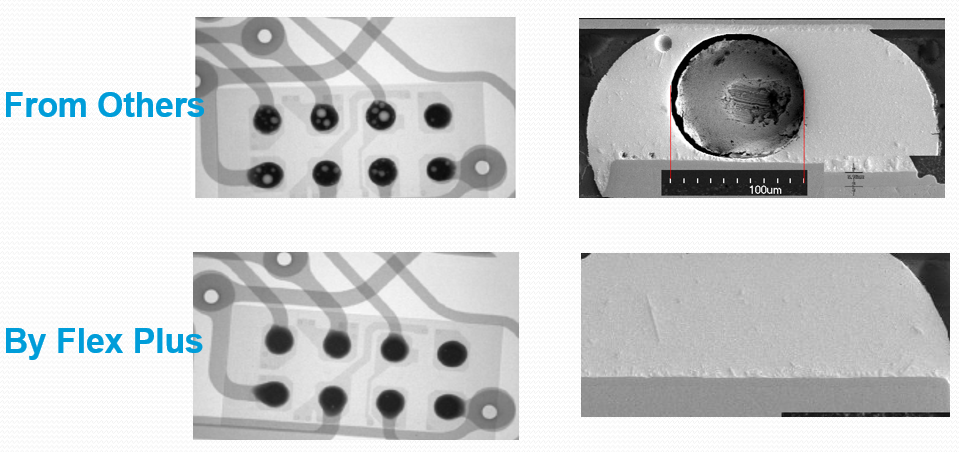

Solder Joint Void Control

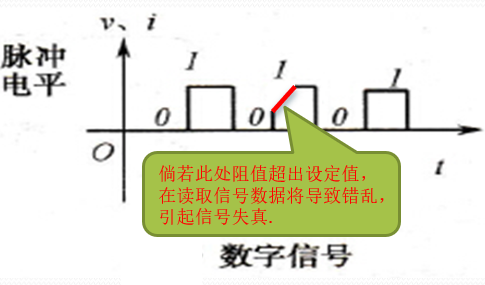

One of the critical factors that Flex Plus focuses on is the control of solder joint voids. By adjusting the reflow curve of the solder paste and components, they achieve the best balance point to reduce the occurrence rate of voids, ensuring the stability of the micro-resistance of the circuit. If the resistance value of the loop exceeds the design value, it will affect the resistance value when reading the signal data, leading to signal confusion and distortion of the input image.

The causes of voids can be due to the proportion of flux in the solder paste being too large, solvent and water in the flux not being completely volatilized, or organic matter contaminated during operation.

脉冲电平: Pulse Level

数字信号: Digital Signal

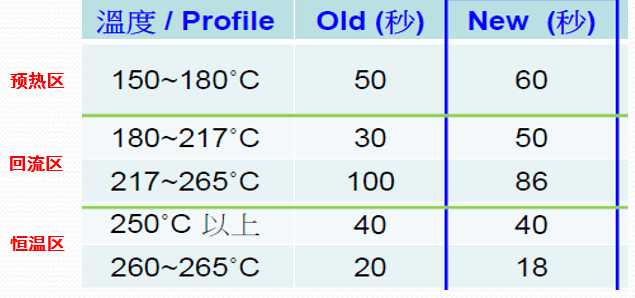

To control voids, Flex Plus selects ALPHA-OM340 solder paste, which has uniform tin powder particles to ensure even heating during reflow soldering, reducing solder beads and voids. They also control the reflow curve in the process to balance the heating rate and time. Additionally, the introduction of nitrogen furnace helps to prevent oxidation during welding and improve the internal quality and reliability of solder joints.

温度: Temperature

秒: Second(s)

预热区: Preheating Zone

回流区: Reflow Zone (FPCB SMT Reflow)

恒温区: Constant Temperature Zone

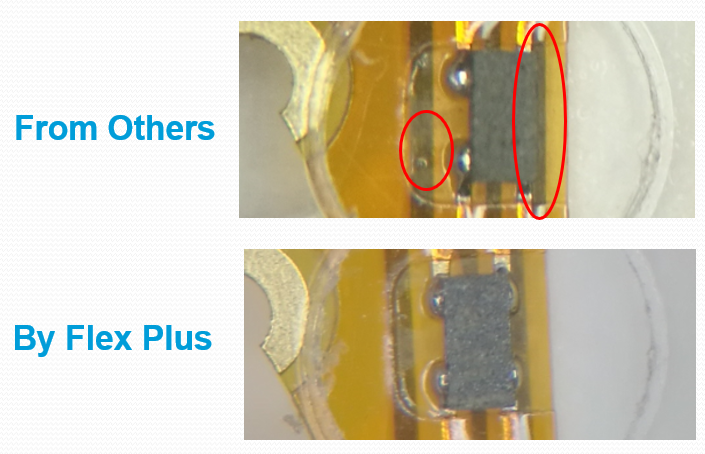

Solder Joint Tin Bead Control

Flex Plus also focuses on controlling the generation of free solder beads. By combining the selection of solder paste, the design of the stencil opening, and adjustment of reflow, they can suppress the generation of free solder beads.

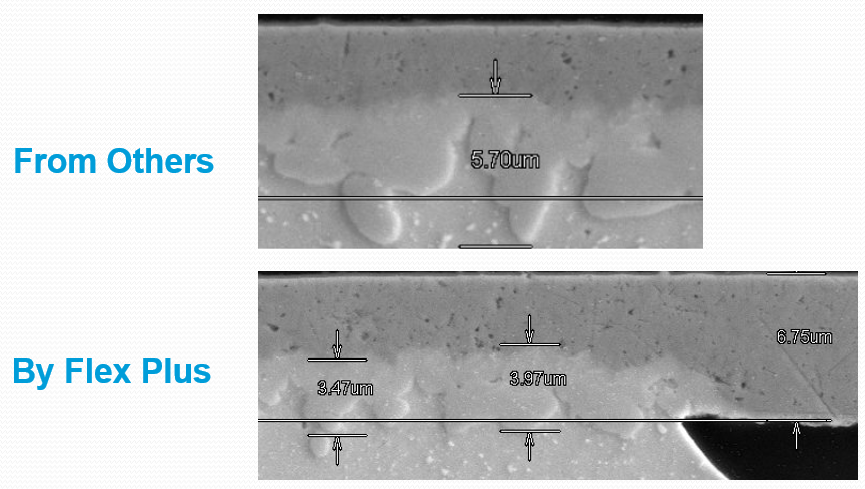

Alloy Layer Balance

Flex Plus controls the alloy layer at 40~60%, which is the best bonding point for components.

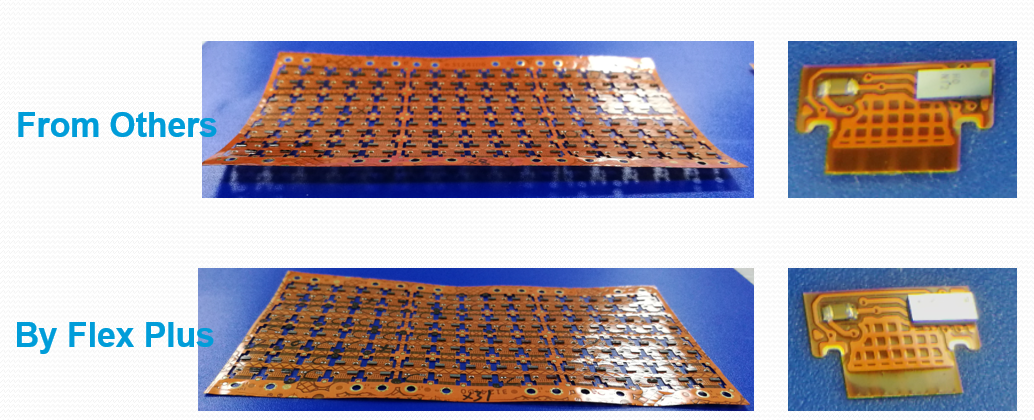

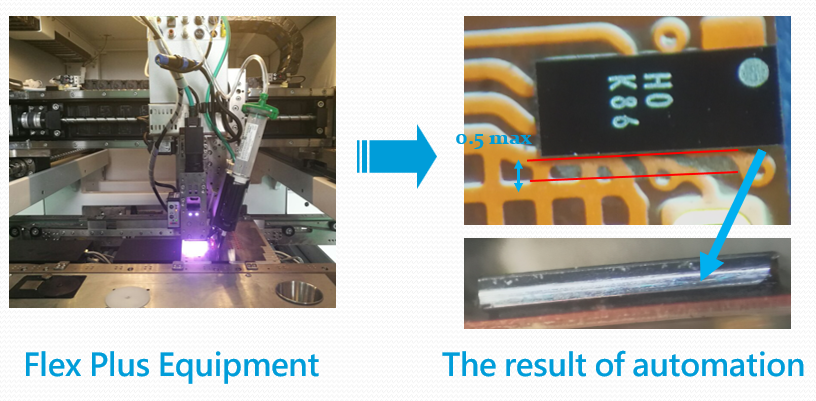

Surface Flatness Control

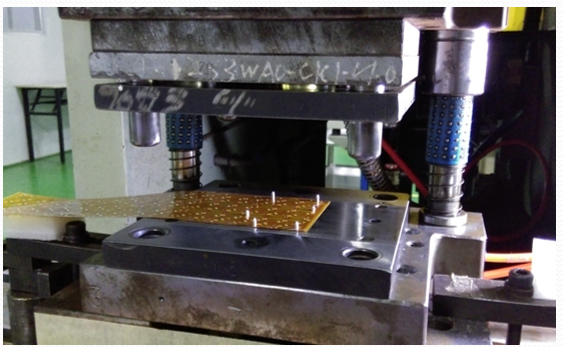

Flex Plus fully releases the stress of FPC in the processing technology and applies a back pin mold design and magnetic fixtures to ensure the flatness of FPC and provide good workability guarantee for automatic assembly.

To control the flatness of the board surface, Flex Plus applies an automatic belowed-PIN(Pin will be extracted to beneath) HardTooling mold to prevent the product from being pulled out, causing wrinkles and deformation. We also use an automatic PIN return HardTooling mold to reduce the unevenness of the board surface, which can cause component displacement and warping during part punching.

Underfill Application

Flex Plus uses IC bottom filling glue to enhance the thrust of the components and act as a buffer when falling, ensuring the reliability of the components. They use Loctite UF3808 capillary underfill, which is designed to cure quickly at low temperatures to minimize stress to other components.

The dispensing equipment is fully automatic, and the specifications are a glue overflow of 0.1mm MAX (*4) and dispensing surface marks of 0.5mm MAX (thickness ≤ 0.005mm).

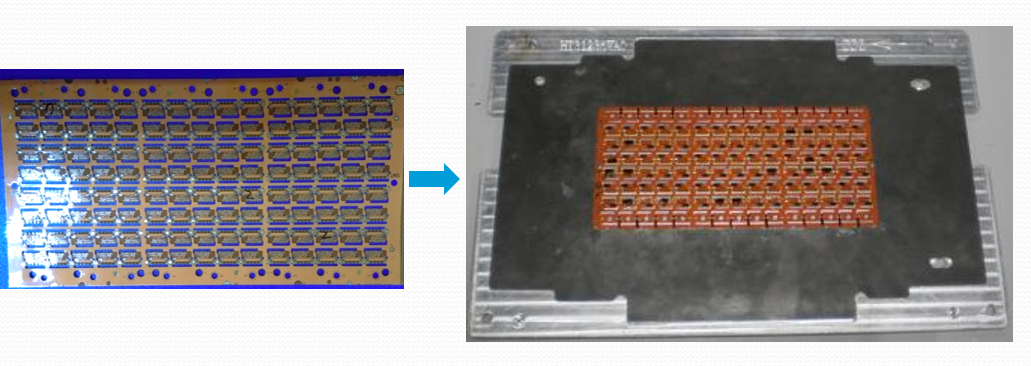

Flex Plus Unique concept of Packaging Design for VCM

Flex Plus's packaging design meets anti-static requirements, has a good protective effect, and can pass the anti-drop test. It is also convenient for customers to use during their automation assembly.

In conclusion, Flex Plus's strength in manufacturing FPC for VCM lies in their control of solder joint voids, solder joint tin bead control, alloy layer balance, surface flatness control, underfill application, and unique packaging design. By focusing on these critical factors, Flex Plus can ensure the reliability and stability of their FPCB for VCM.

For FPCB request with gerber drawing/CAD files contact: gm02@fpc-plus.com

Simply discuss with Flex Plus

add +86 184 5004 5626 to your whatsapp

+86 is country code